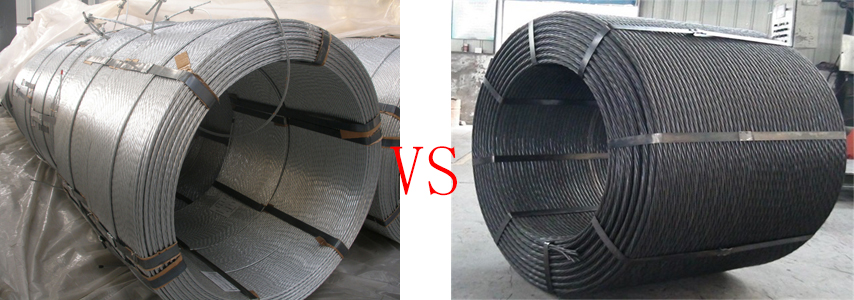

Galvanized steel strand:

Galvanized steel strand is a steel product formed by twisting multiple galvanized steel wires together.

Basic Information:

a. Steel strands are divided into four structures according to the cross-sectional structure: 1×3 1×7 1×19 1×37

b. The national standard steel strand is divided into five grades according to the nominal tensile strength: 1270MPa, 1370MPa, 1470MPa, 1570MPa, 1670MPa.

c. According to the difference in the thickness of the zinc layer of the steel wire in the galvanized steel strand, the level of the zinc layer of the steel wire in the national standard steel strand is divided into three grades: A, B, and C.

Features:

1. Good flexibility 2. Good stability 3. Good reliability 4. High strength

Skills Requirement:

Folding size and accuracy

1. The diameter of the steel wire in the strand and its allowable deviation should meet the standard requirements

2. The lay length of the steel strand should be no more than 14 times its diameter.

3. The twist direction of the outermost layer of the steel strand is the right twist. The twist direction of the outermost layer of steel wire should be opposite to that of the adjacent inner layer of steel wire as shown in the figure below. If the twist direction needs to be changed, it should be indicated in the contract. Strand Twist Direction The strand lay should be left lay (S).

4. Without special requirements, the length of the steel strand shall not be less than 200m, and its length deviation is:

Nominal length Allowable deviation

<1000m +3%

≥1000m +1.5%

Raw Material:

The steel wire for steel strand shall be manufactured according to the wire rod specified in YB/T 170.2 and GB/T 4354. The grade is selected by the supplier.

The zinc ingots for steel wire galvanizing shall be Zn99.995 zinc ingots in GB/T 470.

Folding strand process requirements:

1. The inner steel wire (including the central steel wire) of the steel strand should be of the same diameter, the same strength, and the same zinc layer level.

2. The diameter and lay length of the steel strand should be uniform and not loose after cutting.

3. The steel wires in the steel strand should be tightly stranded? There should be no staggering, breaking and bending.

4. The steel strand should be straight, soft, and small in residual stress. After unfolding, there should be no ∽ shape.

5. Joints are not allowed for 1×3 structural steel strands and overhead ground wires. The inner steel wire joints of other types of steel strands should be welded butt joints, and the distance between any two joints should not be less than 50m. The joints should be treated with anti-corrosion.

Appliaction:

Galvanized steel strand is usually used for messenger wire, guy wire, core wire or strength member, etc. It can also be used as earth wire/ground wire for overhead power transmission, The barrier cable on both sides of the road or the structure cable in the building structure.

The structure is 1 × 7, and the galvanized steel strands with the specifications of 5.4, 6.0, 6.6 and 9.0 can be used for the overhead cable of the postal utility pole.

Production standards:

YB/T5004-1993 Galvanized steel strand

YB/T098-1997 Galvanized steel strand for optical cable

YB/T5004-2001 Galvanized steel strand

Prestressed Concrete steel strand:

Prestressed steel strands are stranded steel cables consisting of 2, 3, 7 or 19 high-strength steel wires, and treated for stress relief (stabilization), suitable for prestressed concrete and similar applications.

Features:

It has high strength and good relaxation properties, and it is more straight when unfolded. The common tensile strength grade is 1860 MPa, and there are strength grades such as 1720, 1770, 1960, 2000, and 2100 MPa. The yield strength of this steel is also high.

Material:

The prestressed steel strand is mainly made of cold-drawn high-carbon steel, and there are traces of phosphide and lubricant residues on the surface.

When the strength is particularly high (such as 2300 MPa), it is necessary to add alloying elements such as chromium, and galvanized high-strength products can increase the silicon content.

Some prestressed steel strands made of carbon steel have coating materials on the surface, such as zinc, zinc-aluminum alloy, epoxy resin, grease and high-density polyethylene sheath.

Stainless steel can also be used to make prestressed strands, using high-strength duplex stainless steel.

Application:

Prestressed steel strands are mainly used in post-tensioned and pre-tensioned prestressed concrete projects.

Die-drawn strands are mainly used in lifting projects, but also in projects such as nuclear power.

19-wire large-diameter steel strands are often used for mine tunnel support anchor cables.

Unbonded prestressed steel strands are often used for building floors and some rock and soil anchor cables.

Production standards:

GB/T 5224-2014; ASTM A416 / A416M-18; BS 5896: 2012; JIS G3536; EN 10138-3; AS/NZS 4672; NBR-7483

Post time: Jan-21-2022